Welcome to Ramsay Electric Co., Ltd

Toggle Navigation

Báscula de Cinta Ramsey Serie 20

Sistema de báscula sobre cinta transportadora para pesar con precisión materiales a granel

La báscula de cinta Ramsey Serie 20 controla elcaudal de alimentación en procesos de trituración,molienda, clasificación y otros, con una precisióndel ±0.5%, incluso en las aplicaciones más difíciles.La báscula de cinta Ramsey Serie 20 le permite

controlar e inventariar la producción o regular elaporte del producto, a la vez que le proporciona información esencial para una gestión efectiva yuna operación eficiente de la productividad.

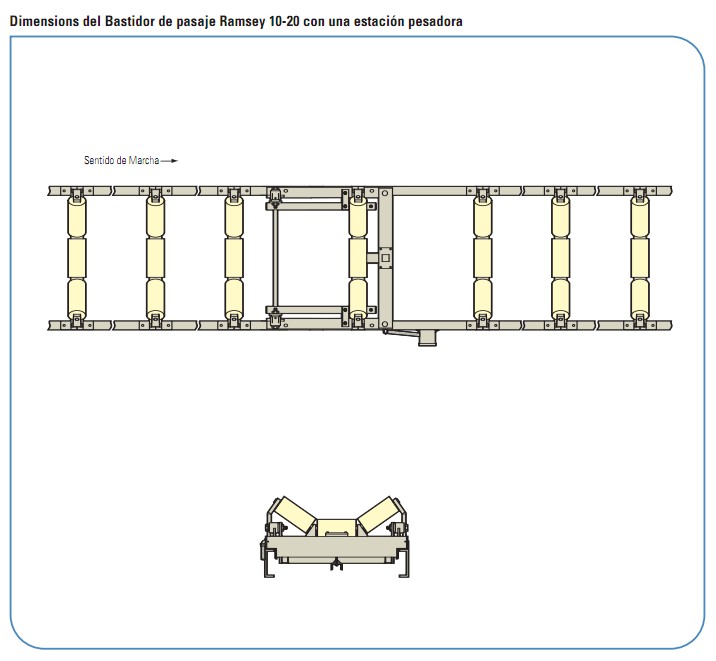

Diseñada para aplicaciones generales de pesaje con cinta transportadora en los entornos industriales más exigentes, el sistema de báscula de cinta Ramsey Serie20 de Thermo Electron Corporation le permite controlar el caudal de alimentación en procesos de trituración,molienda y clasificación, entre otros, con una increíble precisión. Puede controlar e inventariar la producción o controlar el aporte del producto, a la vez que le proporciona información esencial para una gestión efectiva y una operación eficiente de control de la productividad. La báscula de cinta Ramsey Serie 20 combina la probada fiabilidad del bastidor Ramsey 10-20 (conuna estación pesadora) o del bastidor 10-22(con dos estaciones pesadoras) y el sensor

digital de velocidad Ramsey 60-12 con la potencia y la avanzada tecnología del integrador electrónico Ramsey Micro-Tech

Serie 2000 o Serie 3000. Para más información acerca de los integradores electrónicos Ramsey Micro-Tech, consulte

el catálogo PI8011.0703.

Aplicaciones

• Plantas trituradoras• Plantas químicas• Plantas asfálticas• Minas• Plantas de cemento• Lavaderos de carbón

• Reciclado de papel• Fábricas de yeso• Canteras y graveras• Centrales Térmicas• Planta de concentración de minerales

• Carga de vagones y extractores de placas

Fácil instalación

Fácil de instalar en interior o al aire libre, encintas fijas o móviles, la sólida construcción de la báscula de cinta Serie 20 de Ramsey puede instalarse en las aplicaciones más duras y en sitios diversos.Bastidor de pesaje Rígido y sólido, los bastidores de pesaje 10-20 y 10-22 de Ramsey se mantienen permanentemente alineados con la estructura de la cinta. Este bastidor robusto,pero de sencillo aspecto, viene ensamblado de fábrica y se instala sobre la cinta de forma rápida y fácil. Está diseñado para proporcionar una robustez y estabilidad adicionales, con lo que se reduce el margen de error de la cinta. Tanto los modelos de bastidor con una o dos estaciones pesadoras,ofrecen tres puntos de suspensión y utilizan

pivotes sin fricción tipo rótula. Gracias a la estanqueidad de estas unidades, no se ven afectadas por vibraciones, humedad o acumulación de producto, lo que elimina problemas comúnmente asociados a los fieles tipo cuchilla y cojinetes.

Sensor de velocidad de cinta

El sensor digital de velocidad de la báscula Ramsey 60-12 de Thermo es el dispositivo más fiable y preciso de detección de velocidad jamás desarrollado para uso en cintas. Para asegurar una precisa lectura de la velocidad de la cinta, se acopla directamente al tambor de cola, en un rodillo habilitado o en un rodillo de retorno de gran diámetro. No siendo necesario medidores tipo roldana sobre la banda, por lo que se eliminan problemas de acumulación de producto, deslizamientos y desgarros por corte.Ventajas del Bastidor de pesaje

• Sin piezas móviles ni sujetas a desgastes• Célula de carga a tracción que garantiza el alineamiento y una muy buena precisión• Deflexión total máxima de los rodillos menor que 0,102 mm.• Perfil delgado para reducir la acumulación del material• Opcional: Bastidor contrapesado para aplicaciones de baja carga.Ventajas del sensor de velocidad de báscula

• Carcasa robusta fabricado en PRFV apta instalaciones en exteriores• El generador de pulsos C.A. elimina el uso de escobillas y su desgaste Garantía de funcionamiento En las instalaciones aprobadas en fábrica garantizamos que la

báscula de cinta Ramsey Series 20 pesa y totaliza a un valor dentro del ±0,5% del valor de prueba, si se calibra con un peso de prueba conocido, una cadena o un calibrado electrónico normal de Thermo.