Welcome to Ramsay Electric Co., Ltd

Toggle Navigation

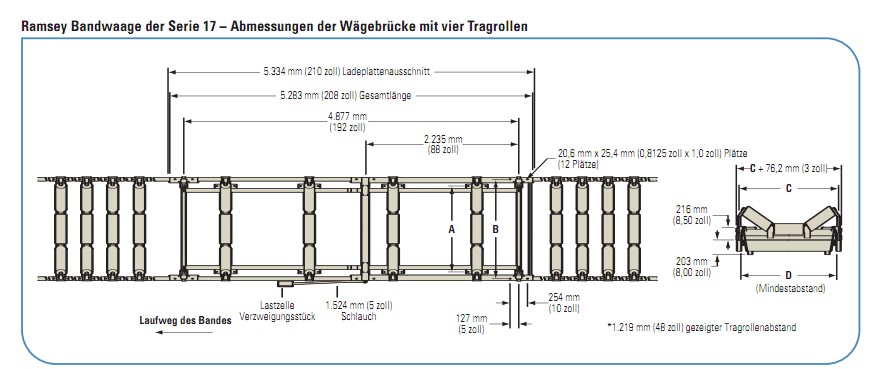

Ramsey Serie 17 Bandwaagen-System

Genaues Wiegen von Schüttgut auf dem Förderband

Das Ramsey Bandwaagen-System der Serie 17 ist speziell für Fabrik- und Prozessanwendungen vorgesehen, die bei hoher Geschwindigkeit ablaufen oder die überdurchschnittliche Genauigkeit von ±0,25 % erfordern. Mit der Ramsey-Serie 17 können Sie den Produktionsausstoß und den Lagerbestand überwachen oder die Produktentladung regeln.Gleichzeitig werden lebenswichtige Informationen für das effektive Management und effiziente Betriebsprozesse in Ihrem Unternehmen bereitgestellt.

Das Ramsey Bandwaagen-System der Serie 17 der Thermo Electron Corporation kombiniert die bewährte Zuverlässigkeit der Ramsey 10-17 Wägebrücke und des Ramsey 60-12 Bandgeschwindigkeitssensors mit der Leistungsstärke und Vielseitigkeit der modernen Elektronik der Ramsey Integratoren der Serien Micro-Tech 2000 und 3000.Die lange Wägebrücke der Ramsey-Serie 17 macht dieses Modell zu einem hochpräzisen Wägesystem mit einer Genauigkeit von

Durch die längere Wägebrücke befindet sich das Material länger auf der Waage, was Ausrichtungsfehler minimiert. Dies übersetzt sich in höhere Genauigkeit. Dieses Bandwaagen-System ist in Versionen mit zwei oder vier Tragrollen erhältlich. Mehr Informationen zur Ramsey Micro-Tech Serie elektronischer Integratoren finden Sie unter Katalognummer PI.8011.0703.

Anwendungen

Das Ramsey Bandwaagen-System der Serie 17 ist für Fabrik- und Prozessanwendungen vorgesehen, die mit höherer Geschwindigkeit ablaufen oder eine überdurchschnittliche Bandwaagengenauigkeit erfordern. Das System überwacht den Produktionsausstoß, steuert die Produktentladung und verfolgt den Lagerbestand. Gleichzeitig werden lebenswichtige Informationen für das effektive Management und effiziente Betriebsprozesse in Ihrem Unternehmen bereitgestellt.

Die Wägebrücke

Das Ramsey Bandwaagen-System der Serie 17 von Thermo Electron enthält die widerstandsfähige, robuste Wägebrücke Ramsey 10-17 mit geringer Auslenkung. Das System ist in allen Bandbreiten und Tragrollenabständen erhältlich.

Der Bandgeschwindigkeitssensor

Der digitale Bandgeschwindigkeitssensor Ramsey 60-12 von Thermo ist das zuverlässigste und genaueste Geschwindigkeitserfassungsgerät,das jemals für Bandwaagen entwickelt wurde. Die direkte Kopplung

des Sensors an die Umlenk- oder Umkehrtrommel des Förderbandes oder eine Umlenkrolle von großem Durchmesser sorgt für eine präzise Messung des Bandweges. Es werden keine Räder auf das Band gesetzt, wodurch Probleme mit Stauung und Abgleiten des Materials vermieden werden.

Vorteile der Wägebrücke

• Die reibungsfreien, abgedichteten Zapfenachsen sind völlig undurchlässig gegenüber Vibrationen, Feuchtigkeit und Materialansammlungen

• Die lange Wägespannweite minimiert Bandeffekte (standardmäßig vier Tragrollen, optional zwei Tragrollen)

• Starre mechanische Röhrenkonstruktion

• Zwei Lastzellen mit Hochpräzisions-Dehnungsmessern unter Spannung montiert für Stabilität und weniger Ausrichtungsfehler

• Gesamtauslenkung der Tragrolle(n) unter 0,127 mm (0,005 Zoll)

• Schmales Profil, so dass Probleme mit Materialstauungen minimiert werden

• Passt in jedes Standard-Förderband, kein Raum über dem Band erforderlich

Vorteile des Bandgeschwindigkeitssensors

• Widerstandsfähiges Gehäuse aus gegossenem Aluminium,geeignet für Außeninstallation

• Wechselstrom-Pulsgenerator, d.h. keine Bürsten einzustellen oder auszutauschen

Leistungsgarantie

Bei werksseitig zugelassenen Installationen gewährleisten wir, dass das Ramsey Präzisionsbandwaagen-System der Serie 17 Wäge- und Zählergebnisse liefert, die um nicht mehr als ±0,25 % von der Testladung abweichen, wenn es gegen ein bekanntes Testgewicht, eine Kette oder die elektronische Standardkalibration von Thermo kalibriert wird.